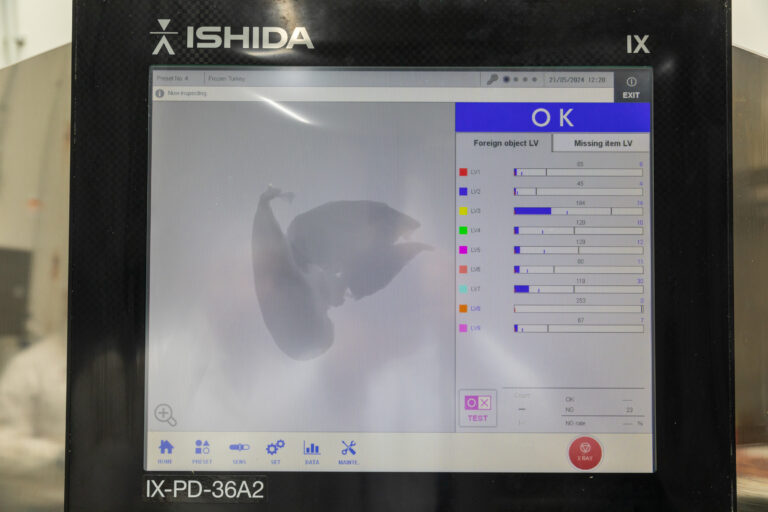

Ishida’s IX-PD-36 X-ray inspection system has been installed at cold-cut meats specialist Nikas’s factory in Attica, Greece. The high-performance technology is being used to inspect fresh chicken, reducing the risk of contaminants such as bones and metal reaching consumers.

Capable of checking up to 80 chicken pieces per minute and operating for 16 hours a day, the IX-PD-36 system detects the smallest foreign bodies. Its advanced image processing and ultra-high resolution capabilities also reduce false alarms, helping to maintain high production speeds.

“The Ishida IX-PD has taken our quality standards to a new level,” said Nikas Plant Director Konstantinos Laitsas. “It not only identifies contaminants but also helps trace and resolve any quality issues quickly.”

Nikas, which supplies the foodservice and retail sectors in Greece and exports to five other countries, had previously used metal detectors for quality checks. The switch to X-ray technology has improved detection across a wider range of contaminants and product types, especially in overlapping or irregularly shaped items.

Nikas is planning to install three more X-ray machines within the next two years.