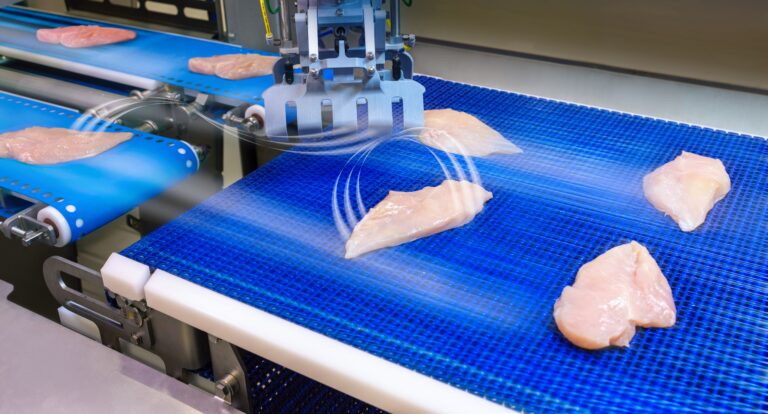

A new robot developed by JBT Marel is promising to transform poultry processing by automating one of the most labour-intensive steps in quick-service restaurant (QSR) production.

The RoboOptimizer uses technology to orient chicken breast fillets before cutting, a critical step for producing consistent fillets, strips, and cubes. By eliminating manual handling, the system reduces giveaway, improves yield, and helps processors.

Each fillet is scanned and analysed so the robot can determine the optimal orientation. This ensures strips are cut to the correct length and fillets fit standard buns. The technology also distinguishes between left and right fillet, an essential factor in product quality and acceptance, according to JBT Marel product specialist Morten Dalqvist.

The system’s software automatically rejects faulty products, such as trimmings, overlaps, or out-of-spec fillets, before they enter the cutter. “RoboOptimizer’s intelligence knows exactly when to skip a product,” Dalqvist said. “This ensures reliable operation at all times.”

When integrated with JBT Marel’s I-Cut 122 TrimSort system, the RoboOptimizer enables processors to create a wide range of consistent, high-quality breast meat products tailored for QSR menus.

“It’s all about maximising yield through higher levels of automation, while still creating products that meet the requirements of QSR brands,” Dalqvist added.