Iain Campbell is the poultry technical manager at Techna for the UK, Ireland and Scandinavia. Techna is an international group that excels in the precision nutrition sector. Here Iain gives some insight into what Precision Nutrition means to Techna and how they use R&D led learning to deliver performance and economic returns for the Broiler Grower.

For six decades Techna have been working alongside agricultural industries providing expertise in livestock farming techniques, precision nutrition, and natural health solutions for both animal and plant production.

By providing high-quality independent technical expertise and effective Product solutions their aim is to boost the profitability and productivity of their clients. With staff actively engaged in the field, Techna are a recognized and influential leader in the animal nutrition and health sector.

In this discussion we learn how Techna apply precision nutrition and exactly what it means to them. Commonly promoted these days the term ‘Precision Nutrition’ is sometimes taken for granted. However, if you really want to be precise about nutrition you need to invest in scientific research to push the depth of knowledge and find the fine detail which create benefits. In effect creating a ‘Precision Nutrition Plus’ operation. Techna achieve this by operating the largest privately owned Poultry research centre in Europe.

Techna say that two most important aspect of large-scale broiler production is a healthy digestive tract and optimising the feed costs.

If we want to optimise broiler feed cost fully it requires a multi-factorial approach that goes far beyond simply managing the optimisation of broiler feed recipes using formulation software. It requires precise knowledge of the raw materials used, considerable expertise in feed digestibility and knowledge of nutritional strategies which can manage the diets given the commercial and contractual arrangements between the farmer and the processor.

Techna has used investment in R&D to create a highly accurate broiler specific Energy matrix. They also challenge the given book values of enzymes such as NSP’s, Phytase, Amylase, Protease and Lipase through rolling digestibility trials to determine the actual matrix value / benefit. This method of accurate matrix building is generated from thousands of digestibility trials on additives and raw materials.

1. RAW MATERIAL CHARACTERISTICS & VARIABILITY CONTROL

The raw materials used in animal nutrition are numerous, diverse and complementary. Studying their intrinsic characteristics is fundamental to understanding the nutritional potential of each one, as well as identifying the anti-nutritional components that can limit their use in feed. Strategies adapted to the nature of the anti-nutritional factors, such as plant selection, the application of heat treatment or the incorporation of enzymes into the feed, are known levers for maximising the animal’s use of the nutritive compounds in the raw materials.

Controlling the quality of raw materials through regular chemical or NIR analyses is another essential element in guaranteeing a stable, high-performance feed. It enables the measurement and consideration of the raw materials’ actual nutrient content, which can vary to a greater or lesser extent from one supply to another. For example, the simple fact of considering a one-point drop in moisture in the maize formulation matrix results in a saving of around £1/t of feed. This is due to the higher energy value provided by the drier maize.

This detailed knowledge of raw materials and the control of their variability through the use of evolving raw material matrices when formulating feed is the first lever for optimising feed costs.

2. FEED DIGESTIBILITY IS THE KEY TO HIGH-PERFORMANCE FEEDS

The nutritional contribution of raw materials is only optimised if the bird is able to absorb these nutrients through the intestinal epithelium.

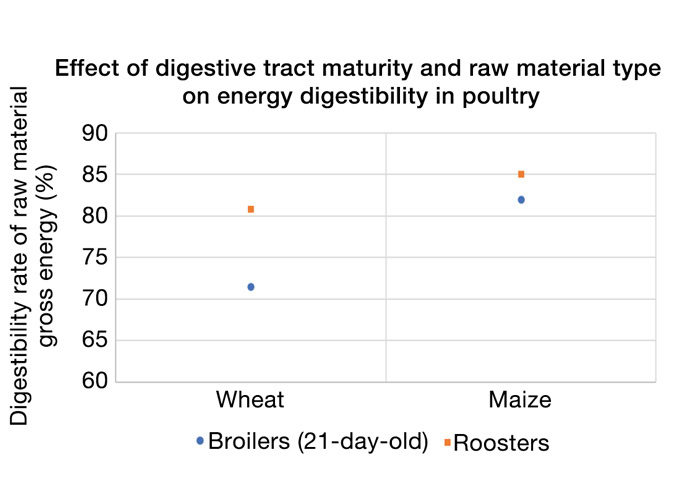

The digestibility of a feed depends on several factors. Depending on their structural and nutritional composition, not all raw materials have the same capacity to be digested by the animal. Added to this is the physiological stage of the bird, which will also have an impact on the digestibility of the raw materials contained in the feed. A study conducted over the last 20 years on our research farm examining the digestibility of various feedstuffs in 21-day-old broilers and adult birds reveals significant differences in their ability to digest and utilize different ingredients. These variations depend on the birds’ physiological stage and the specific feedstuff, as illustrated by the example of wheat and maize (Graph 1).

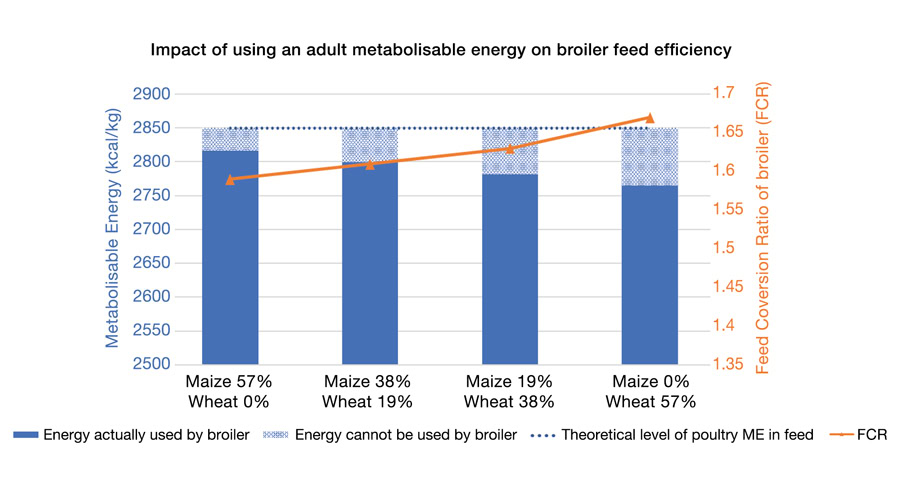

When optimising a range of broiler feed, considering the capacity of young animals to digest raw materials less efficiently is an important lever for feed performance. As shown in Graph 2, formulating poultry feed for growing broilers using Metabolisable energy values derived from adult bird digestibility data can significantly affect overall feed costs by worsening the feed conversion ratio.

Four groups of broilers are fed with different recipes with the same nutritional level but different proportions of wheat and maize. A level of 2850 kcal/kg of adult metabolisable energy (Poultry ME) is used to formulate these four recipes. The Feed Conversion Ratio is measured for each broiler group.

To address this issue, TECHNA has developed a Broiler Metabolisable Energy (Broiler ME) value specifically tailored for growing broilers. This ensures an adequate energy supply, accounting for their digestive capacity, which differs from one raw material to another and is also more limited than that of an adult animal. Working on feed formulation to adapt it to the specific physiological characteristics of growing broilers ensures that feed performance is maintained, whatever the composition of the feed.

Finally, the optimal functioning of the digestive tract plays a central and decisive role in maximising the value of the feed ingested by the animal. The structural and functional integrity of the digestive tract is therefore sought through the dynamic balance between intestinal flora, immunity and digestive integrity. As a result, the digestive tract emerges as the key competitive factor in the poultry industry.

Drawing on its knowledge of the physiological effects of essential oils and plant extracts, TECHNA offers Aviance, a combination of aromatic phenolic compounds protected by an innovative coating, which increases the surface area of absorption in the duodenum and jejunum. The synthesis of numerous French and international trials indicates an improvement of 2.90% and 3.50% respectively in growth and feed conversion. Thus, using Aviance in a nutritional matrix could generate a gain of £3 to £4 for equivalent performance.

All these prerequisites make it possible to work accurately and reliably on the nutritional requirements of the animals and to study the various possible strategies for refining the overall feed cost depending on the context.

3. MODELLING NUTRITIONAL REQUIREMENTS THROUGH META-ANALYSIS OF OVER 30 TRIALS

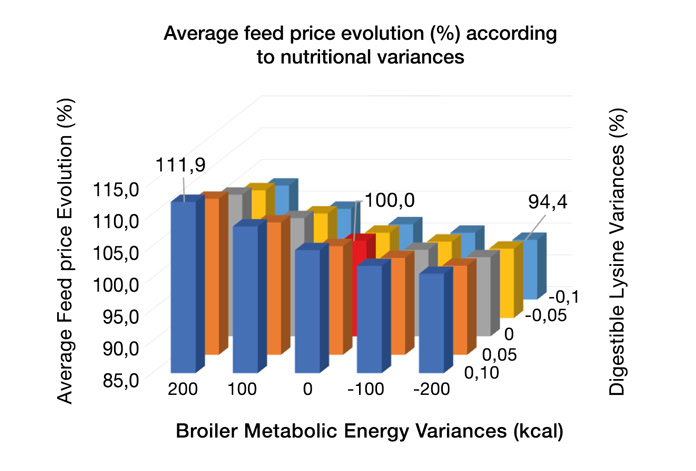

The compilation of over 30 nutritional trials in the form of a meta-analysis makes it possible to predict broiler performance (weight, technical FCR, fillet and thigh yield) according to two nutritional criteria: Broiler Metabolisable Energy and Digestible Lysine. These prediction equations are incorporated into our Wefeed Projection decision-support software. However, the results need to be modulated to take account of the effect of the terrain on station rearing conditions.

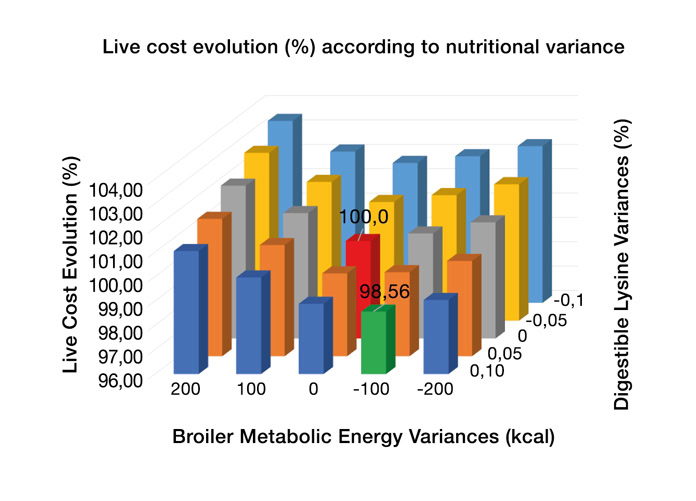

The results of the Wefeed Projection simulations show how important it is to consider the various links in the production chain when choosing the right nutritional standards. The combination of energy and digestible lysine, which is the most economical in terms of feed price (Graph 3), does not correspond to the most efficient nutritional scenario for optimising the cost price of live animals (Graph 4).

CONCLUSIONS

By optimizing nutrient utilization, precision nutrition reduces the amount of undigested nutrients excreted, leading to lower environmental pollution. Reducing environmental impact by lowering excretion rates of nutrients like nitrogen contribute to a more sustainable poultry industry.

Feed cost management must be approached holistically, a principle at the heart of TECHNA’s longstanding expertise in precision nutrition. By characterizing the nutritional profile of raw materials and controlling their intrinsic variability while considering the broiler’s digestive capacity, it becomes possible to develop an optimal nutritional strategy that achieves zootechnical goals at the lowest cost. In conclusion, precision nutrition in poultry diets is a promising approach for improving production efficiency, reducing environmental impact, and enhancing bird health. As technologies continue to advance like artificial intelligence and machine learning and our understanding of poultry metabolism deepens, precision nutrition is poised to play an increasingly significant role in the future of poultry production.

Learn more at groupe-techna.com