In high volume processing plants, it is important to make the best of each individual fillet. This means the optimum use of raw material, truly minimal give-away and maximum profit.

How do consumers want their fillets?

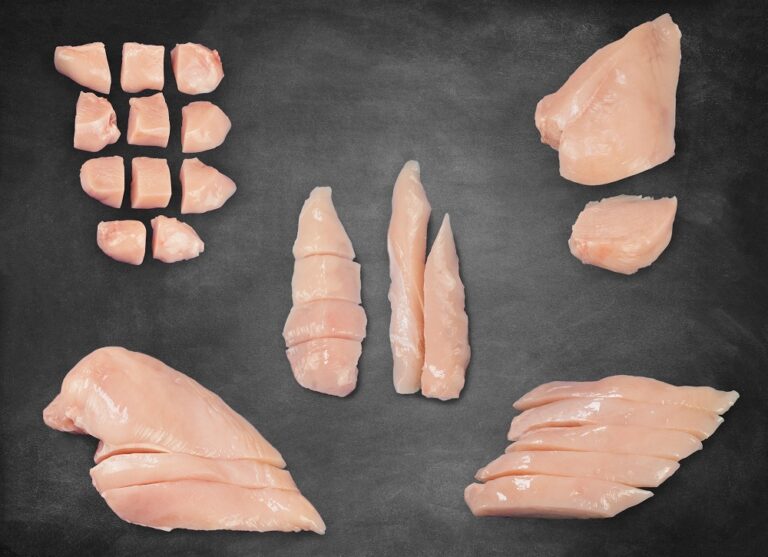

Most people eat their breast meat products either at home or in a restaurant. In both cases, their choice will depend on family size and taste. This could be for fillets, tenderloins, medallions, strips, nuggets or cubes, each with its own detailed specification. Products should look and weigh the same and it should be possible to produce them in large volumes. Only high-speed intelligent portioning equipment can achieve this. Such systems should preferably have dual lanes and it should be easy to change from one portioning option to another.

How to cut a large chicken breast?

Broilers are becoming heavier with their large breast fillets increasingly difficult to accommodate on retail tray packs. These packs often have a fixed weight and a fixed price. Heavier fillets, however, make it more difficult to hit the required pack weight, resulting in avoidable and unwanted give-away. Portioning fillets to a uniform size and weight is an excellent solution to this problem. Intelligent equipment, making use of smart software, will calculate how each fillet can be portioned most effectively to give the best possible use of raw material, reducing any give-away to a minimum and maximising yield.

How to make more of offcuts?

Trim is an inevitable by-product of portioning. You will always have offcuts, however small. These are from top quality muscle meat and can be used to maximum effect in value-added further processed products. To realise their full potential, even the smallest pieces must be managed efficiently. It may sound obvious but the best way to do this is to automatically separate trim from the main product in a controlled way, so that both proceed on separate conveyor systems to their next destination in the process. Valuable off-cuts don’t then end up as a bulk low value item; their own dedicated processing line upgrades them to high-quality poultry meat.

How to make portion cuts look natural?

Good presentation is important too. Trimmed breast fillet for sale retail should look natural, as though it has not been trimmed at all. This means cutting with a slanting fillet edge. When cutting medallions, strips, nuggets or cubes, it is particularly important that all portions look identical and weigh exactly the same.

Modern portion cutters work extremely precisely and produce identical natural looking cuts. It is even possible to adjust the angle of cut. This natural look no longer has to result in costly give-away. Today, portioning is a fast process, where every gram counts. Cutting precision is now down to 5 grams. Five grams may seem nothing but it all adds up. Let’s take an example. At 14,400 pieces per hour over an eight hour shift, this comes to 115 kilograms of valuable meat lost per day. When using modern portion cutting equipment, such losses are a thing of the past. No matter how the fillet is cut, it is done precisely, using raw material to maximum effect.

How can technology help optimise portioning fillets?

Using the very latest vision control technology such as laser light together with innovative portioning software, it is possible to determine the exact shape of each fillet and calculate the best possible way of portioning it. A screen shows clearly how fillets are to be cut. Software enables remote programming and the storage of a large number of customer-specific cutting programs in its software menu.

Today’s customers, whether supermarket chains or quick service restaurants, demand a large portfolio of different products from poultry processors. It is therefore important that any portioning system not only handles high hourly volumes but can also handle more than one product specification at the same time. Besides the ability to make different products on different lanes, it must be possible to switch quickly from one product to another. Intelligent software makes such changes a matter of tapping a few keys.

What’s the ultimate in portioning fillets?

Intelligent software is also about collecting data. You don’t know what you don’t know! Having collected data and converted this into useful reports, operators will then have instant access to all key performance indicators presented centrally in a user-friendly format. Only supported by this information can operators keep the equipment performing at maximum efficiency.

Intelligence could then be taken a step further by linking separate intelligent systems. Supposing it were possible to link equipment, a pick and place robot, producing fixed weight tray packs of breast fillet to our intelligent portioning system. The robot would tell the portioner which pieces of meat to trim and by how much; the result would be packs with truly minimal give-away.