By Rachael Porter

The march of robotic technology in the poultry industry – from poultry and egg production right through to processing and packaging – continues to gather pace. This is no doubt fuelled by concerns about labour shortages, particularly with all the uncertainty post Brexit, and the need to increase the speed and efficiency of all tasks along the food chain.

Marel Poultry is just one of many companies addressing these current and future concerns with new technological developments for the poultry industry. It says that sustainability, including issues such as carbon footprint and carcase balance, as well as animal welfare and food safety are driving the development of new automated technologies. It’s not just about the availability of labour.

Processing speed

“A strong market drive towards lower production costs per bird, without compromising on product quality, asks for higher levels of efficiency and productivity in poultry plants,” says Marel’s Anton de Weerd.

“At the same time, the growing world population leads to higher consumer demand for poultry products. And that’s why we currently offer 15,000 bird-per-hour processing – the highest processing speed in the industry.”

The idea behind the 15,000 bph capacity is not so much speed but rather keeping control of efficiency and reliability, in line with demand of processors. “A maximum level of automation is obviously required to realise this kind of productivity,” adds de Weerd.

“And we have automated all processes – from live-bird handling and stunning, via evisceration and chilling, and throughout the distribution line. This is the only way to ensure that every step in the process can handle this high speed and that the labour requirement can be kept to a minimum.”

Greater efficiency also means improved sustainability. The company says that in many instances just slight modifications to machinery will result in significant increase in throughput. “And this means a significant reduction of energy, water and environmental footprint, compared to a full expansion with a second processing line,” says de Weerd.

Control room

A key component in any automated processing plant is the software platform. Marel’s own Innova Food Processing Software has all the modules available to enable automation and robotisation of many applications and tasks.

“Innova plays a major part in increasing the automation level in a poultry processing plant. It gathers data from equipment sensors in all steps of the process and enters these details in a centralised, paperless system,” says the company’s René Kjaer.

The software combines this information to ensure that the plant functions efficiently and it also has the ability to adapt to changing circumstances and interact with the processing system. “When, for example, a flock of larger birds enters the plant, this requires modified machine settings to maintain a consistent product quality for a customer’s order. Our software allows machines to ‘talk’ to each other without human intervention.”

Also key to sustainability is the improved utilisation of raw materials and maximising the value of every part of the chicken. “Using just the breast meat of carefully reared chicken and ‘underrating’ the rest, which is good food that’s rich in protein, makes no sense,” says de Weerd. “It’s vital to add as much value as possible to each and every part of the chicken, particularly to such a tasty part as the leg.”

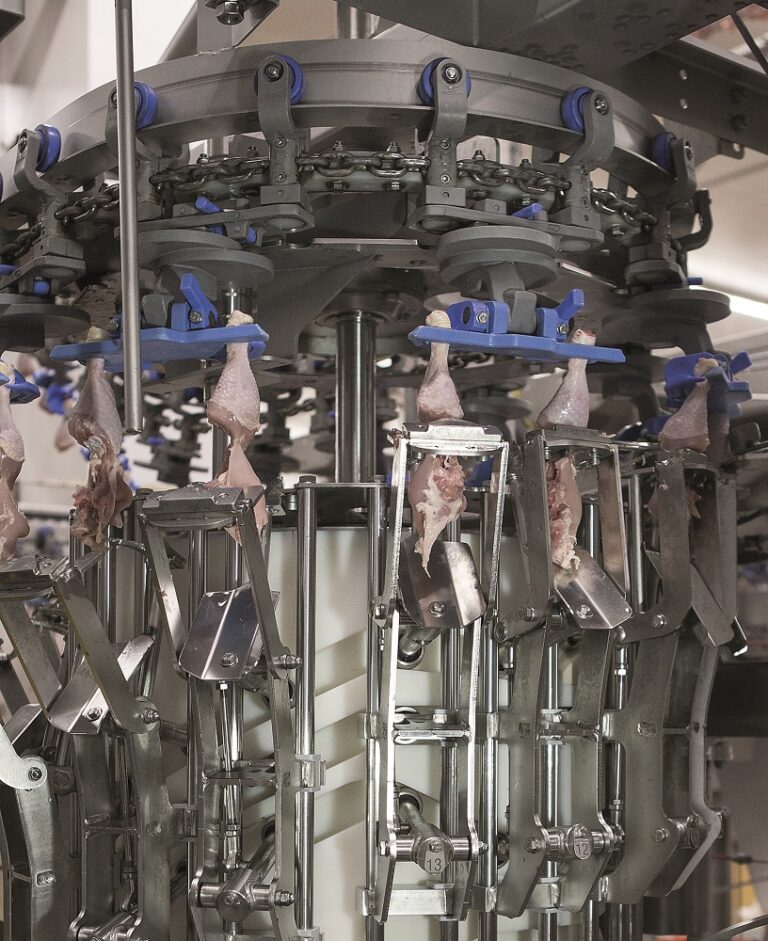

Deboning operation

By automating manual deboning operations, poultry processors can align with this ‘carcase balancing’ trend and also increase cost-effectiveness – deboned meat has more value than bone-in meat. “Automation allows for upgrading of formerly exported frozen bone-in meat parts and turns them into attractive boneless products.

“And we can provide processors with systems that enable them to make maximum use of every part of the broiler. Our latest addition is ‘Total Leg Deboning’, of which the Thigh Fillet System is an important component.”

Reducing ‘give away’ is important too and again automation can help here. “Each part of processed chicken is highly valuable, losing just one gram of meat per product could mean the daily loss of 108kg,” explains portioning product manager Morten Dalqvist. “Maximising product use and avoiding give-away is a key focus for us and that’s why we have developed automated composite solutions, such as the ‘robot with a knife’.”

This comprises the I-Cut 122 Portion Cutter paired with the RoboBatcher Flex. “This intelligent equipment fusion cuts strictly to customer order while the resulting offcuts are batched as valuable products in their own right,” adds Dalqvist.

Conveyer systems

Conveying products through the various stages of a processing line is a basic requirement for automated systems and Interfood Technology is now offering a flexible alternative to conventional belt-based systems.

As the sole distributor in the UK and Ireland for Weber – a brand known worldwide in the high-speed slicing and automation arena – Interfood introduce the Weber Shuttle System (WSS) to the wider food processing industry.

WSS allows products to be conveyed throughout the production process precisely and at optimum efficiency. The system is based on a track system that is non-mechanically driven, allowing multiple scenarios for system design and integration into existing production facilities.

Optimised speeds

Products are conveyed on a carrier that can move them, for example, from depositing stations that require a static depositing target to stations requiring an accurate constant moving target, where spreading is required.

Speeds can be separately controlled in areas such as bends and 180-degree switchbacks – typically points which can cause issues – ensuring the product is handled gently without disruption during optimised conveying speeds.

“Given Weber’s wide-ranging experience in slicing, examples of applications naturally include slicing lines where multiple products are required in the same package or platters,” explains Interfood’s Andre Clareboets. “These products would typically be sliced on individual slicers and then collated and automatically loaded into a packaging machine, typically with a Weber Pick and Place system.

Multiple actions

“However, opportunities are certainly not confined to slicing. For example in ready-meal lines, and other make-up lines such as sandwiches and pizzas where multiple actions are required to create the finished product, the system offers key advantages.

“The ability to move the product between each operation and easily select stations and positions by product type allows for complete flexibility and easy product changeovers. Buffering areas, weighing stations and manual correction areas can all be created with the addition of an in-line cleaning system for the product carriers, ensuring product safety.”

Better safety

Clareboets adds that the system is completely safe when it’s ‘in use’, due to its lack of mechanical drive systems, and operators can interface directly with the equipment without risk and without the need for barriers and safety devices.

“We believe the possibilities are endless allowing for the creation of automated industrial food processing systems that offer the ultimate in efficiency.”

WSS can be integrated with Weber’s leading range of established loading and automation systems, such as robotic loading solutions, or integrated with existing systems. “So far the focus has been on selected key areas of the food industry, but the capabilities of the system provide significant advantages for considerably extending its range of applications.”

New partnership set to speed up robotic development for poultry industry

Such is the pace of demand for automation – to combat issues with sourcing labour and to add speed and precision, as well as safety and traceability, to the processing line, that two companies – Gibotech and Sanovo Technology Group – have joined forces to create Sanovo Technology Robotics A/S.

This company has, to date, developed a system that can handle different breeds of bird by measuring the breast cap on the AMF-i filleting system. This is a new robot cell for Sanovo’s palletising facility.

But a lot more has been going besides developing the robot cell, which was completed in just four weeks. The two neighbouring companies have been exploiting the advantages of being situated side by side in Odense, Denmark, which is rapidly becoming known as the country’s robot capitol and is now has more than one more robotics company.

As well as being part of Thornico, a global conglomerate owned by the Stadil family, Sanovo Technology Group is one of the world’s largest suppliers of machines and equipment for handling of eggs and egg products. The new joint organisation will make Sanovo Technology Robotics the sole supplier of Sanovo Technology Group and the company will develop automation and robotics solutions for the group’s various business areas.

“And our goal is simple – to become the world’s leading supplier of robotics solutions for the egg industry,” says Sanovo Technology Group’s chief executive Michael Midskov.

“We are number one in the world within our field. And now we are going to expand our position to also include automation with robots and AGV systems. We believe that cooperating with Gibotech, combined with our knowledge about the market and building complete process lines, will make us strong together.”